Our experience in microfluidics market demonstrates a thorough understanding of applications and industries. We use this knowledge to shape the future of microfluidics, and continuously push the boundaries to find new and better ways to solve scientific challenges. Explore our customer stories to learn how our products helped them to achieve the results they wanted and optimize their processes.

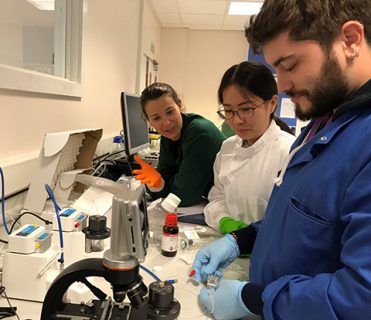

Hydrogel microfiber structures have great potential in biomedicine, enabling modelling of the dimensions, mechanics and complexity of different biological tissues and disease pathologies, including cancers. There have been significant advances over the past decade in creating complex hydrogel shapes and geometries, using microfluidics for the controlled crosslinking of precursor molecules. So far, this strategy has required a different microfluidics set-up for each distinct morphology, and each set-up can only achieve a limited number of geometries. Scientists are therefore keen to identify a flexible microfluidics system that can fabricate various architectures and geometries for a diverse range of biological applications. To this end, the 3B’s Research Group at the University of Minho has developed a novel biofabrication technique that uses three-dimensional (3D) flow focusing (FF) chips from Dolomite Microfluidics to create complex structures that can mimic biological microenvironments

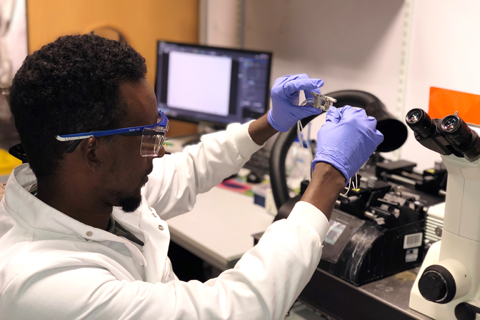

A research group at the University of Manitoba is using microfluidics technologies from Dolomite Microfluidics to design and evaluate novel nanoparticle drug delivery systems for the safe and effective treatment of diseases during pregnancy. The laboratory has developed an innovative microfluidics model to mimic the structure of the placenta, and is using this system to assess the potential of new nanoparticle-based therapies for serious congenital diseases, such as diaphragmatic hernia.

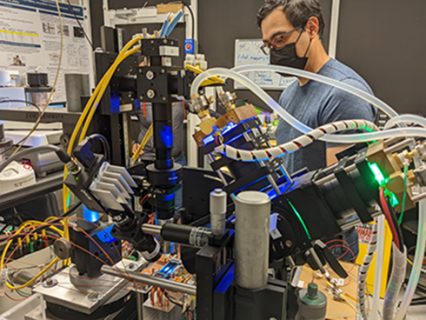

Scientists at the Palo Alto Research Center (PARC), are using a novel microfluidic technique – spectral optical calorimetry (SPOC) – during their screening processes to determine when molecules bind to the specific disease-related targets. This exciting new application will help improving drug delivery and therapeutic efficacy.

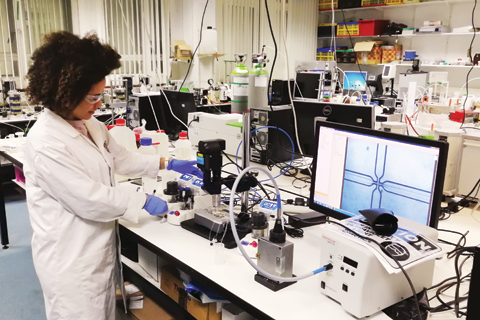

Scientists from the Division of Pharmacy and Optometry at the University of Manchester are using microfluidics to optimize the production of liposome nanoparticles for reliable drug delivery and therapeutic efficacy.

Researchers at the Ludwig Maximilian University of Munich are using microfluidics for the production of nanosized siRNA delivery systems to achieve the reproducibility and consistency required for reliable drug delivery.

Researchers in the Department of Plant Biology at the University of Vermont have developed a novel droplet microfluidics approach to investigate plant cell mechanics and increase their understanding of plant development.

Researchers in the School of Pharmacy at the University of Nottingham are using novel techniques to enhance studies on drug encapsulation and therapeutic delivery, optimizing microfluidic reaction conditions to produce fluorescent PLGA to act as a biosensor, storing and releasing biological medicines dependent on environmental changes.

Researchers at the University of Cambridge are using microencapsulation technologies developed by Dolomite Microfluidics to develop self-healing construction materials. Dr Livia Ribeiro discusses the challenges associated with producing these microcapsules, and the benefits that microfluidics offers over other methodologies.

Are you using our product(s) in your research or production? If yes, tell us how it helped you to achieve the results you wanted and optimize your processes. In exchange, we will assist you in gaining positive media coverage, by promoting it in relevant publications, free of charge.

A research group at the University of Manitoba is using microfluidics technologies from Dolomite Microfluidics to design and evaluate novel nanoparticle drug delivery systems for the safe and effective treatment of diseases during pregnancy.

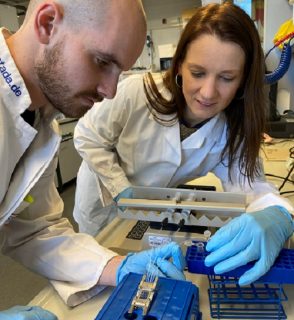

Researchers in the Department of Pharmacy at the Ludwig Maximilian University of Munich are using chips from Dolomite Microfluidics to reliably and consistently manufacture monodisperse nanoparticles for targeted delivery of small interfering RNA (siRNA) therapeutics.

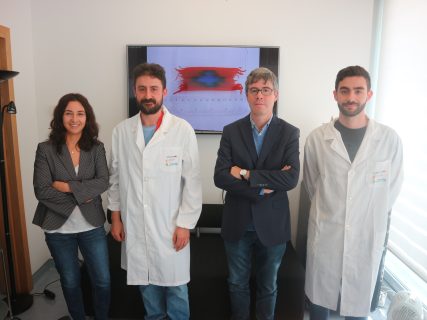

Researchers at the University of Porto, Portugal are using Dolomite Microfluidics chips to manufacture diverse therapeutic nanoplatforms, including an advanced microfluidic method for manufacture of taxane-loaded nanoparticles for cancer treatment.

A Dolomite Microfluidics’ set-up is helping researchers in the University of Manchester’s Division of Pharmacy and Optometry to enhance drug delivery by formulating PLGA drug delivery systems for oncology applications, and liposomes for the co-delivery of fat- and water-soluble therapeutics.

Kenshi Yaginuma, Wataru Aoki, Natsuko Miura, Yuta Ohtani, Shunsuke Aburaya, Masato Kogawa, Yohei Nishikawa, Masahito Hosokawa, Haruko Takeyama, Mitsuyoshi Ueda

Scientific Reports

10.1038/s41598-019-47388-x

Since G-protein coupled receptors (GPCRs) are linked to various diseases, screening of functional ligands against GPCRs is vital for drug discovery. In the present study, we developed a high-throughput functional cell-based assay by combining human culture cells producing a GPCR, yeast cells secreting randomized peptide ligands, and a droplet microfluidic device. We constructed a reporter human cell line that emits fluorescence in response to the activation of human glucagon-like peptide-1 receptor (hGLP1R). We then constructed a yeast library secreting an agonist of hGLP1R or randomized peptide ligands. We demonstrated that high-throughput identification of functional ligands against hGLP1R could be performed by co-culturing the reporter cells and the yeast cells in droplets. We identified functional ligands, one of which had higher activity than that of an original sequence. The result suggests that our system could facilitate the discovery of functional peptide ligands of GPCRs.

Yiming Feng, Youngsoo Lee

Journal of Food Engineering

10.1016/j.jfoodeng.2018.10.028

Wrinkled microcapsules have attracted great interest due to their distinguished features, including enhanced adhesion propensity and release profiles. These features could be beneficial for food-related applications and improve the bioavailability of encapsulated compounds by promoting their attachment to epithelium. However, the fabrication of such microcapsules with food-grade materials has been met with limited success. In this study, a facile approach to produce wrinkled microcapsules using a food-grade protein, zein, is proposed. Internal phase separation was used to form zein microcapsules and three acids (phytic acid, citric acid, and succinic acid) were incorporated at two centration levels (10 mM and 20 mM) to modify the secondary structure of zein in the microcapsules. The results showed that the mechanical properties of the microcapsules, which were characterized by nanoindentation, were greatly dependent on the protein secondary structure, particularly the α-helix structure. The morphology of the microcapsules was evaluated by image analysis. An extensive wrinkle was observed on the surfaces of the microcapsules with high viscoplasticity. Among the three acids used in this study, phytic acid significantly increased the degree of wrinkling and viscoplasticity of the microcapsules. Further characterization with circular dichroism and wide-angle X-ray scattering suggested that a less ordered zein secondary structure was formed in the samples prepared using phytic acid than in those prepared using other acids or without acid, which further supports the hypothesis that the nanomechanical properties and degree of wrinkling are associated with the protein secondary structures.

Julien Rosselgong, Maud Chemin, Cedric Cabral Almada, Gauvin Hemery, Jean-Michel Guigner, Guillaume Chollet, Gilles LABAT, Denilson da Silva Perez, Frederique Ham-Pichavant, Etienne Grau, Stéphane Grelier, Sebastien Lecommandoux, Henri Cramail

Biomacromolecules

10.1021/acs.biomac.8b01210

This work aims at designing functional biomaterials through selective chemical modification of xylan from beechwood. Acidic hydrolysis of xylan leaded to well-defined oligomers with an average of six xylose units per chain and with an aldehyde group at the reductive end. Reductive amination was performed on this aldehyde end-group to introduce an azide reactive group. ‘Click chemistry’ was then applied to couple these hydrophilic xylans moieties with different hydrophobic fatty acid methyl esters that were previously functionalized with complementary alkyne functions. The resulting amphiphilic bio-based conjugates were then self-assembled using three different methods, namely direct solubilization, thin-film rehydration/extrusion and microfluidics. Well-defined micelles and vesicles were obtained and their high loading capacity with propiconazole as an antifungal active molecule was shown. The resulting vesicles loaded with propiconazole in a microfluidic process, proved to significantly improve the antifungal activity of propiconazole, demonstrating the high potential of such xylan-based amphiphiles.