Microfluidic solutions to generate monodispersed water-in-oil-in-water (w/o/w) or oil-in-water-in-oil (o/w/o) droplets, emulsions or particles.

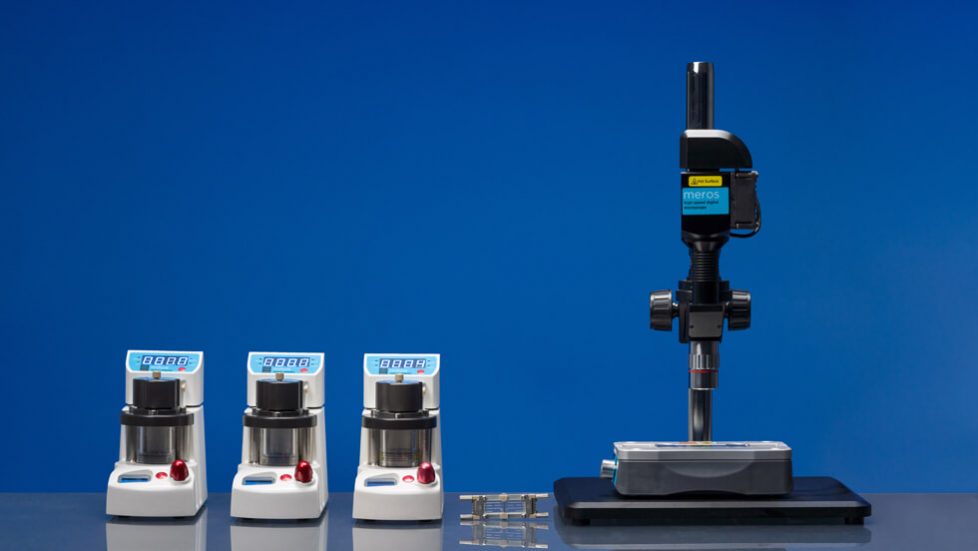

Microfluidic solutions to generate monodispersed water-in-oil-in-water (w/o/w) or oil-in-water-in-oil (o/w/o) droplets, emulsions or particles. Our versatile double emulsions systems apply dynamic flow-focusing microfluidic methods for production of emulsions with monodisperse outer and inner droplets or particles, sizes ranging from 50 to 250 µm.

Based on our precision micro manufactured glass chips, the Double Emulsion Systems give the possibility for the user to choose between a one-chip method (where the output of the first junction flows directly into a second junction on the same chip) or a two-chip method (where the first emulsion is collected in a recipient first, then introduced in the second chip) to generate double emulsions in a reproducible and controlled manner. The size, materials and monodispersity of droplets, particles, capsules, foams and emulsions can be precisely controlled, enabling novel formulations. This ensures users of reproducible and consistent production of double emulsions.

Microfluidics, also known as a ‘lab-on-a-chip’, enables the precise control, manipulation and analysis of fluids in the microlitre to picolitre range. Furthermore, it allows the manipulation of living matter by mixing, separating and handling different components at a microscale.

Dolomite is pioneering the use of microfluidic devices for small-scale fluid control and analysis, enabling engineers and scientists to take full advantage of the following benefits:

Making Double Emulsions is an advanced microfluidic application that requires the droplet forming flow channels to have both hydrophobic and hydrophilic properties on separate sections. It is largely used in food, cosmetics and pharmaceutical industries.

Microfluidic encapsulations can protect or separate unstable (incompatible) ingredients or protect materials from oxidative degradation in cosmetics. Otherwise, flavours or APIs can be encapsulated in droplet capsules with time-controlled release or different materials created in a series of shells.

|

Droplet size |

Droplets (o/w/o or w/o/w) ranging from 50 μm to 200 μm |

|

Droplet monodispersity |

Extremely monodisperse, CV < 5%. |

| Droplet generation frequency | Up to 10 kHz for a standard system and up to a MHz for a Telos® production system (depending on reagents and droplet sizes). |

| Flow rate range |

From 70 nL/min to 5 mL/min, depending on pressure, viscosity and channel geometry (flow resistance). |

| Flow pressure |

Flexible with vacuum and pressure capability in the same pump (pump pressure range: 0-10 bar). Pumps contain integrated reservoir to eliminate the risk of vial fracture in operation. |

| Chemical resistance |

Very high (wetted materials: glass, PEEK, ETFE, FEP, PTFE). |

Telos® High-Throughput Production Systems provide a controlled solution for scaling-up droplet, particles or emulsion manufacturing. Each Dolomite Microfluidic System has a flexible configuration which allows up to 10 Telos® Clamp Modules to be assembled in parallel, enabling identical conditions for scale-up of production rate for up to 500,000 monodisperse particles per second.

Read about our single channel droplet generation systems, if this is too advanced for your application. Or if you simply are exploring other opportunities.

This publication focuses on how double emulsions are designed to provide protection to bioactives in the innermost compartment through encapsulation and prevent the loss of functionality in food matrix as well as during the GI transit.

Read about how double emulsion microcapsules were used at cement-based material manufacture, for extending the service life of concrete infrastructure, using bulk emulsifications polymerisation techniques.