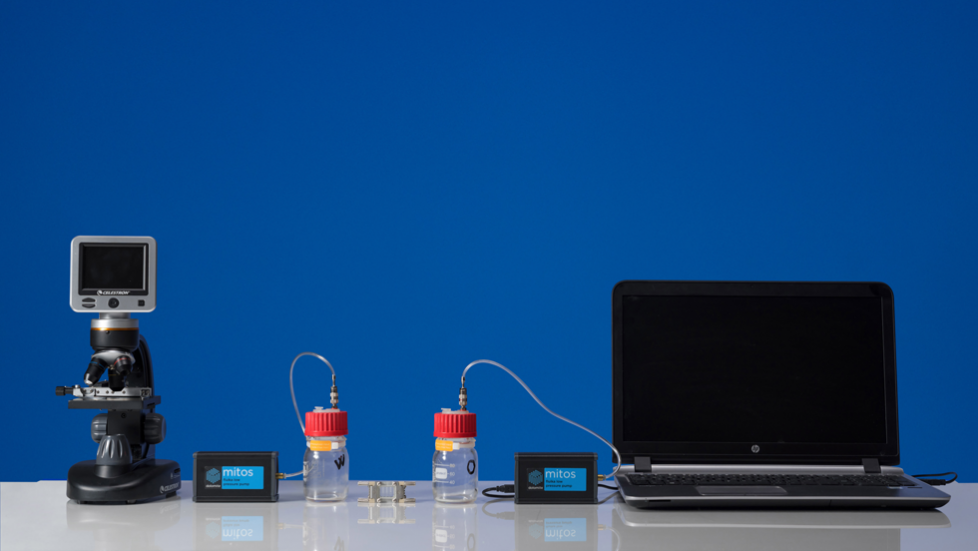

The modular starter system offers hands-on understanding of microfluidics in a convenient, cost effective and very flexible way. The aim is to introduce and emphasize microfluidic concepts such as laminar flow, diffusion, and allow practical learning of methods for droplet generation, mixing of fluids or monitoring of fluid flow. Plus, provide all data users will need to grasp the understanding of microfluidics.

The Starter system is an ideal tool for practical lab teaching sessions. For example, students can design experiments to test the effect of flow rate on diffusional mixing, setup the equipment, run the experiment, and capture images for their lab reports.

This microfluidic compact system can be a perfect solution for busy laboratories too. The ability to use small fluid volumes means that hazardous fluids can be used in a controlled way. This helps not only to track experimental protocols or procedures, but also promotes the utilisation of microfluidics at an earlier stage.

Microfluidics, also known as a ‘lab-on-a-chip’, enables the precise control, manipulation and analysis of fluids in the microlitre to picolitre range. Furthermore, it allows the manipulation of living matter by mixing, separating and handling different components at a microscale.

Dolomite is pioneering the use of microfluidic devices for small-scale fluid control and analysis, enabling engineers and scientists to take full advantage of the following benefits:

Droplet production is important when using immiscible fluids (most commonly water based with additives or salts and mineral oil, paraffins, fluorocarbons, etc.). For many applications which use traditional batch methods is nearly impossible to generate monodisperse droplets with consistent characteristics, avoiding wastage and weighty loss of final product.

Whilst microfluidics accomplishes the production of highly uniform droplets with almost 0% wastage. Precise flow control, high yields and monodispersity are main keys to achieve these results.

|

Droplet size |

Droplets (w/o or o/w) ranging from 1-2 μm to 200 μm. |

|

Production volume |

In the millilitre range. |

|

Droplet monodispersity |

Extremely monodisperse, CV < 5%. |

| Droplet generation frequency | Up to 500 Hz. |

| Flow rate range |

Up to ml/min. |

| Flow pressure |

Flexible pressure capability in the same pump (pump pressure range: 0-500 mbar). Safe pressure vessel design eliminates the risk of vial fracture in operation. No pressured gas-supply required as pumps are powered by a standard USB port. |

| Chemical resistance |

Very high (wetted materials: glass, PEEK, FEP, FFKM, FKM). |

4 chips supplied as standard parts (Micromixer chip, Y-junction chip, Hydrophobic droplet chip and Hydrophilic droplet chip) to allow a range of experiments. However, all other Dolomite chips can be purchased and used with this setup. Additionally, the compact set-up includes digital microscope with image storage capability

Use our microfluidic calculator to discover which flow rates, pressure and chip diameters may be required to achieve the laminar flow for your application.

Methodology for production of monodisperse droplets with sizes ranging from 5 μm to 250 μm using mixing and flow focusing methods.

Read about benefits of a microfluidic approach in producing monodisperse polymer micro- and nanoparticles in a reproducible and scalable way.