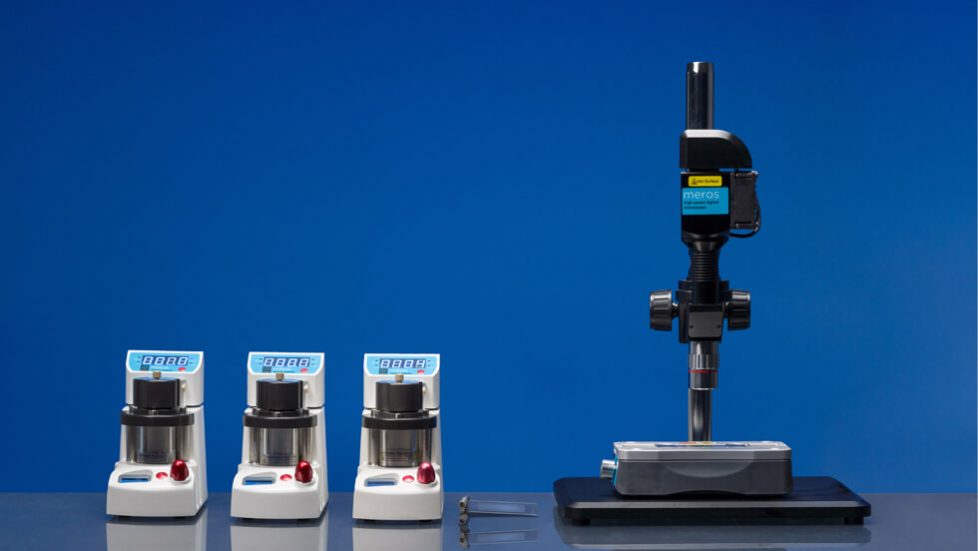

The ideal microfluidic solution for the study and modulization of liquid flows in porous rocks.

The ideal microfluidic solution for the study and modulization of liquid flows in porous rocks. Microfluidic technologies are ideal for the development of new methods to extract crude oil which can be trapped in porous rock, mixed with contaminants, or be in a dynamic state where the extraction method may have to be altered quickly. Using high-quality microfluidic chips developed in collaboration with professor Marcio Carvalho from PUC-Rio, the Porous Media System allows easy pumping, mixing, optical measurements, as well as modelling of fluid flow in porous rock at given temperature and pressure.

Microfluidics, also known as a ‘lab-on-a-chip’, enables the precise control, manipulation and analysis of fluids in the microlitre to picolitre range. Furthermore, it allows the manipulation of living matter by mixing, separating and handling different components at a microscale.

Dolomite is pioneering the use of microfluidic devices for small-scale fluid control and analysis, enabling engineers and scientists to take full advantage of the following benefits:

Characterization of flow through rock is necessary to be able to effectively extract crude trapped in porous rock. Fluid flow through porous media is very complex and difficult to analyze optically. Crude movement in rocks is limited by parameters such as connectivity and tortuosity. Furthermore, the flow is influenced by complex interactions between the fluids themselves and the geometry and surface of the pore spaces.

Microfluidic technologies can aid with the assessment and the development of new test methods to extract crude which can be trapped in porous rock, mixed with contaminants, or be in a dynamic state where the extraction method may have to be altered quickly.

|

Microfluidic device |

Chip channel grid has randomly distributed pores to imitate a naturally occurring rock structure, for a better understanding of the displacement mechanisms in porous media. |

| Sample volume | From 0.5 mL to several liters |

| Operating temperature |

1-125 ºC (higher with custom devices) |

| Flow frequency | Up to 10 kHz for a standard system and up to a MHz for a Telos® production system (depending on reagents and droplet sizes). |

| Flow rate range |

From 70 nL/min to5 mL/min (depending on pressure, viscosity and flow resistance). |

| Flow pressure |

Flexible with vacuum and pressure capability in same pump (pump pressure range: 0-10 bar). However, with custom devices a pressure of up to 30 bar may be attained. Pumps contain integrated reservoir to eliminate the risk of vial fracture in operation. |

| Flow monitoring |

The High Speed Digital Microscope captures the fluid flowing in chip channels for easy monitoring. |

| Chemical compatability |

Very high (wetted materials: glass, PTFE, PEEK, FFKM). |

Learn more about of the modelling of complex porous rock structures and how microfluidic chips enable applications in oil and gas extraction, environmental testing and groundwater analysis.

Read about how scientists explored the dispersion of data such as capillary desaturation curves and secondary waterflood recoveries using micromodels of different sizes and different pore patterns.

Read about findings which demonstrate that microfluidic experiments using translucent grains and fluids are a convenient tool for quantitative investigation of sub-resolution liquid/liquid displacement in porous media.