Our microfluidic systems have enabled rapid advances in droplet generation, enabling users to produce monodispersed droplets ranging from 2 to 200 µm.

Our microfluidic systems have enabled rapid advances in droplet generation, enabling users to produce monodispersed droplets ranging from 2 to 200 µm. Using our innovative flow focusing methods users can reliably produce water-in-oil (w/o) or oil-in-water (o/w) droplets, made from one, two or three reagents.

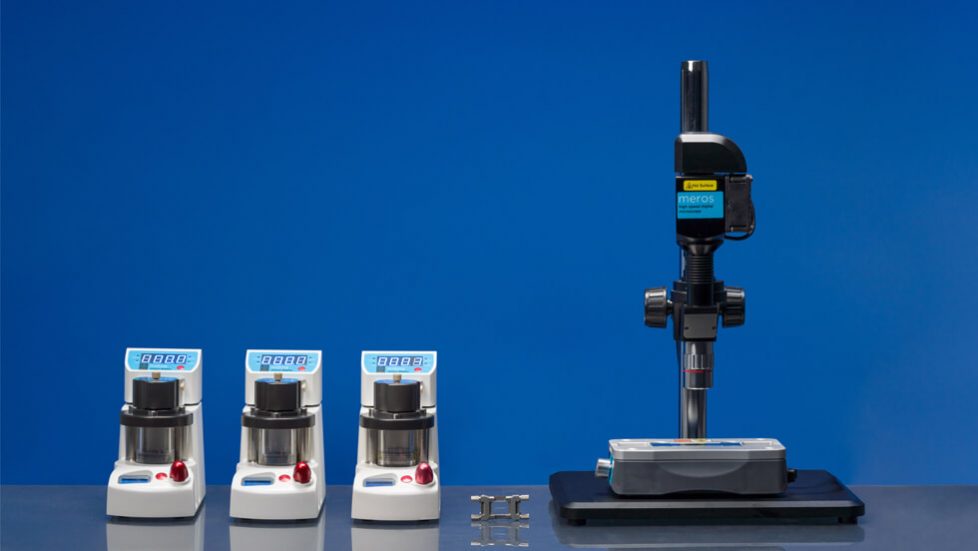

Our systems are designed to produce highly monodispersed droplets, emulsions and Janus particles; allowing to produce up to 10,000 droplets per second. Thanks to their modularity, our Single Emulsion Generation Systems provide users with a very cost-effective scale-up with Telos® technology.

Microfluidics, also known as a ‘lab-on-a-chip’, enables the precise control, manipulation and analysis of fluids in the microlitre to picolitre range. Furthermore, it allows the manipulation of living matter by mixing, separating and handling different components at a microscale.

Dolomite is pioneering the use of microfluidic devices for small-scale fluid control and analysis, enabling engineers and scientists to take full advantage of the following benefits:

Microfluidic techniques offer a solution for production of extremely consistent sizes of droplets, particles, bubbles or emulsions (e.g. 1% coefficient of variation). This guarantees high control and reproducibility which is fundamental from research to production scale.

Traditional batch methodologies struggle to produce monodisperse droplets leading to final products with consistent characteristics, avoiding wastage and weight loss. In contrast, microfluidics users need only choose the right surfactants, carrier fluids, flow control and microfluidic chip to produce monodispersed droplets time and time again. Precise control of flow rates and pressures virtually eliminates errors and accomplishes almost 0% wastage.

|

Droplet size |

Droplets (w/o or o/w) ranging from 2 μm to 200 μm. |

|

Droplet monodispersity |

Extremely monodisperse, CV < 5%. |

| Droplet generation frequency | Up to 10 kHz for a standard system and up to a MHz for a Telos® production system (depending on reagents and droplet sizes). |

| Flow rate range |

From 70 nL/min to 5 mL/min, depending on pressure, viscosity and channel geometry (flow resistance). |

| Flow pressure |

Flexible with vacuum and pressure capability in the same pump (pump pressure range: 0-10 bar). Pumps contain integrated reservoir to eliminate the risk of vial fracture in operation. |

| Chemical resistance |

Very high (wetted materials: glass, PEEK, ETFE, FEP, PTFE). |

Telos® High-Throughput Production Systems provide a controlled solution for scaling-up droplet, particles or emulsion manufacturing. Each Dolomite Microfluidic System has a flexible configuration which allows up to 10 Telos® Clamp Modules to be assembled in parallel, enabling identical conditions for scale-up of production rate for up to 500,000 monodisperse particles per second.

Use our microfluidic calculator to discover which flow rates, pressure and chip diameters may be required to achieve the laminar flow for your application.

Methodology for production of large monodisperse water droplets in an oil carrier stream with droplet sizes ranging from 20 μm to 200 μm.

Methodology for generation of small monodisperse water droplets in a mineral oil emulsion with droplet sizes ranging from 2 μm to 40 μm.