Dolomite’s modular, scalable, and highly flexible system removes the low-throughput limitation of individual microfluidic chips, enabling liters of droplets, emulsions or particles to be produced per day. The production rate achieved on Telos® technology is comparable to those achieved by traditional batch methods. However, it excels against batch methods by generating highly monodisperse droplets.

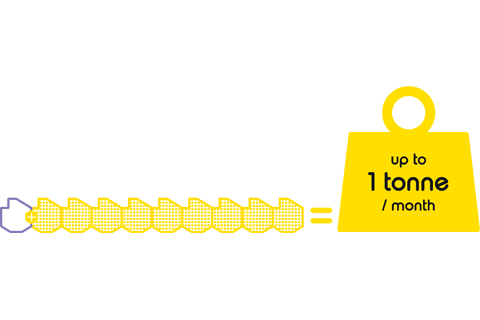

The Telos® System is a breakthrough product for scaling-up microfluidic processes, during which up to 10 Telos® modules can be assembled in parallel. The number of modules is dependent on user needs and application specifics.

The Telos® Clamp Module holds a microfluidic chip. Fast set-up time is achieved with a practical tool-free clamp mechanism that locates and seals the chip in place, making or breaking connections instantly. Plus, module has independent valving, allowing control of input streams, chip replacement and inspection without interrupting droplet production.

The Telos® modular assembly provides a choice to users, to collect production samples vertically in a fluid reservoir as a bulk solution. Or use horizontal orientation output streams which typically are collected into tubing to allow downstream process steps.

Each Telos® Clamp Module holds a microfluidic chip typically with 7 junctions with a typical flow output of 3 mL/min. The system setup of 10 modules enables a total of 70 parallel junctions to be run at once and allows users to produce up to 1 tonne of highly monodisperse droplets per month.

All Telos® Chip junctions are visible from above and below for illumination and optical access. This is a valuable help for rapid maintenance control of individual chips, where fast-acting module valves allow one chip to be replaced without affecting the others and stopping production.

Telos® Modules have integrated valves which provide an excellent flow control during priming, operation and optional integrated filters on all input streams.

Telos® Chips have 7 parallel junctions which assist to achieve the higher throughput for various applications. Depending of chip channel geometries and system setup, users may produce up to 500,000 droplets per second.

We offer a range of universal Telos® Chips. However, custom chips can be designed for the system to take full advantage of scale-up potential. If you would like to generate droplets of a different size, operate with challenging fluids or perform complex droplet functions, Dolomite experts can advise and design the junction geometry required.

Telos® Modules have integrated valves which provide an excellent flow control during priming, operation and optional integrated filters on all input streams.

Some reasons for customization:

Telos® benefits a wide range of industries including pharmaceutical, food, agrochemical, cosmetics and research. Depending on the system configuration, users may efficiently scale-up the production of below applications. Plus, compare microfluidics technology against traditional batch methods.

Methodology for fabrication of monodisperse PLGA beads with sizes ranging from 10 to 40 µm using the Hydrodynamic Flow Focusing Method.

Methodology for generation of monodisperse polyacrylamide beads in sizes ranging from 20 to 220 µm using microfluidic flow focusing method.

|

Droplet size |

Droplets ranging typically from 2 µm to 200 µm (depending on chip) |

|

Droplet monodispersity |

Extremely monodisperse, CV < 5%. |

| Production volume |

From 100 mL to several litres per day |

| Temperature range |

From 4°C to 80°C |

| Droplet generation frequency | Up to several MHz (depending on reagents and droplet sizes) |

| Internal volume per Telos® Clamp Module |

207 µL |

|

Footprint |

100 x 300 x 105 mm (depth x width x height) |

| Flow rate range |

From 1 mL/min to >100 mL/min (depending on number of Telos® Clamp Modules, pump pressure and fluid viscosity) |

| Flow pressure |

Flexible with vacuum and pressure capability in the same pump (pump pressure range: 0-10 bar). Pumps contain integrated reservoir to eliminate the risk of vial fracture in operation. |

| Chemical resistance |

Very high (wetted materials: glass, PEEK, ETFE, FEP, FFKM,PCTFE, PTFE). |

Immerse yourself in the operational aspects, detailed parts specifications and the setup of this system.

This application note describes the operating procedure and performance of the Telos® system for the production of monodisperse water-in-oil emulsions using 35 chip junctions in parallel.

This application note describes how Telos can be used to encapsulate hydrophobic drugs (APIs) in PLGA microparticles.