Microfluidic solutions for the high-throughput encapsulation of cells into picolitre monodisperse droplets.

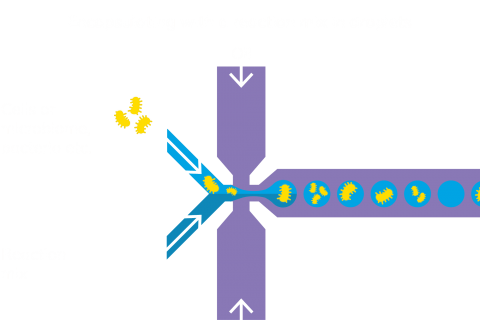

Microfluidic solutions for the high-throughput encapsulation of cells into picolitre monodisperse droplets.In many biological processes, crucial events take place at the level of cells, and these cannot be understood without precise analytical tools. Cells, such bacteria, can be compartmentalized or optionally mixed with reagents in tiny droplets, where each droplet behaves as a discrete micro-reactor. This microfluidic process enables the analysis of many cells, the analysis of rare cells or high-throughput sorting of libraries. It also enables the encapsulation of cells in gel beads for cell therapy applications.

Microfluidics, also known as a ‘lab-on-a-chip’, enables the precise control, manipulation and analysis of fluids in the microlitre to picolitre range. Furthermore, it allows the manipulation of living matter by mixing, separating and handling different components at a microscale.

Dolomite is pioneering the use of microfluidic devices for small-scale fluid control and analysis, enabling engineers and scientists to take full advantage of the following benefits (results may vary):

To encapsulate a sample, the user loads the sample and reagent into two separate 100µl reservoirs, closes the module, and starts the program. During one run of 15minutes, 3 million droplets are being collected in the built-in output reservoir.

Highly monodisperse droplets are being produced with precise control using the pressure pumps. The flow sensors provide real-time display of micro-scale flow rates and allow for accurate adjustment of flow.

The entire cell path (chip junction, sample and collection reservoir) can be maintained at a set temperature (between 1 and 100°C) with the TCU-100 temperature control unit. Droplet production can be monitored with the High-Speed Camera and Microscope System and hardware controlled with the Flow Control Centre software.

|

Applications |

Agarose, Cell-cell interactions, Phage display, Double Emulsions for FACS and other. |

|

Droplet Size |

From 12 µm to 65 µm. Typically, for a given droplet chip, the droplet sizes achievable are the junction width ±25%. |

| Droplet monodispersity | Extremely monodisperse droplets (CV <5%). |

| Droplet volume |

From 1 pl to 500 pl. |

| Droplet type |

Aqueous (biological media). |

| Droplet analysis frequency |

Quantitative analysis of droplet size at low flow rates – typically below 1 kHz – and qualitative evaluation at production speeds of 2-15 kHz or higher, depending on droplet size. |

| Oil types (dispersed phase) |

Typically, a biocompatible fluorinated oil. |

| Flow rate range |

From nl/min to ml/min (dependent upon pressure and flow restriction). |

| Flow pressure |

Flexible with vacuum and pressure capability in the same pump (pump pressure range: 0-10 bar). Pumps contain integrated reservoir to eliminate the risk of vial fracture in operation. |

| Temperature range |

Extremely accurate control of a fixed temperature from 1°C to 100°C. |

| Chemical resistance |

Very high (wetted materials: glass, PEEK, ETFE, FEP, PTFE). |

Hardware (μEncapsulator, 3 pressure pumps, 3 flow sensors, temperature controller, compressor, monitor, microscope and camera), control software (Flow Control Centre Advanced), accessories & consumables (chips, connectors, valves and pipes) and installation & training.

This application note summarises the results of the production of a double emulsion on the µEncapsulator system using a 30µm µEncapsulator 1- 2 Reagent Droplet Chip. It details parameters such as flow rates and pressures.

The cell encapsulation system enables the simple, quick and reliable encapsulation of single cells, DNA and/or functionalized beads in high precision, monodisperse picoliter droplets.

This application note summarises the results of the encapsulation of Agarose and Matrigel on the µEncapsulator system using a 50 µm µEncapsulator 1- 2 Reagent Droplet Chip. It details parameters such as flow rates and temperature, recovery of the hydrogel beads as well as useful tips for cleaning the system after encapsulation of hydrogels.